Waste Management Technology

How can we help you?

Fields marked with * are required

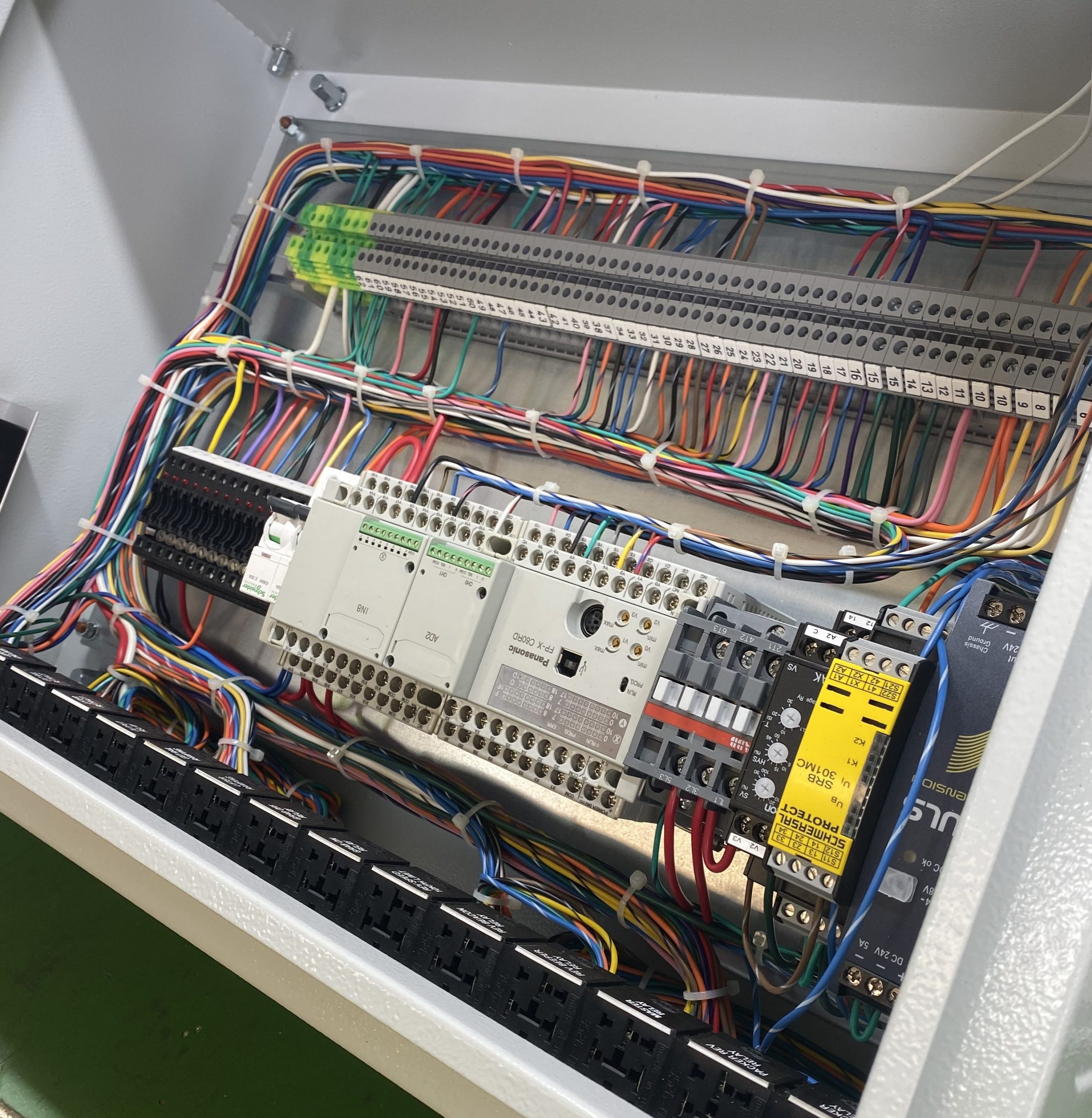

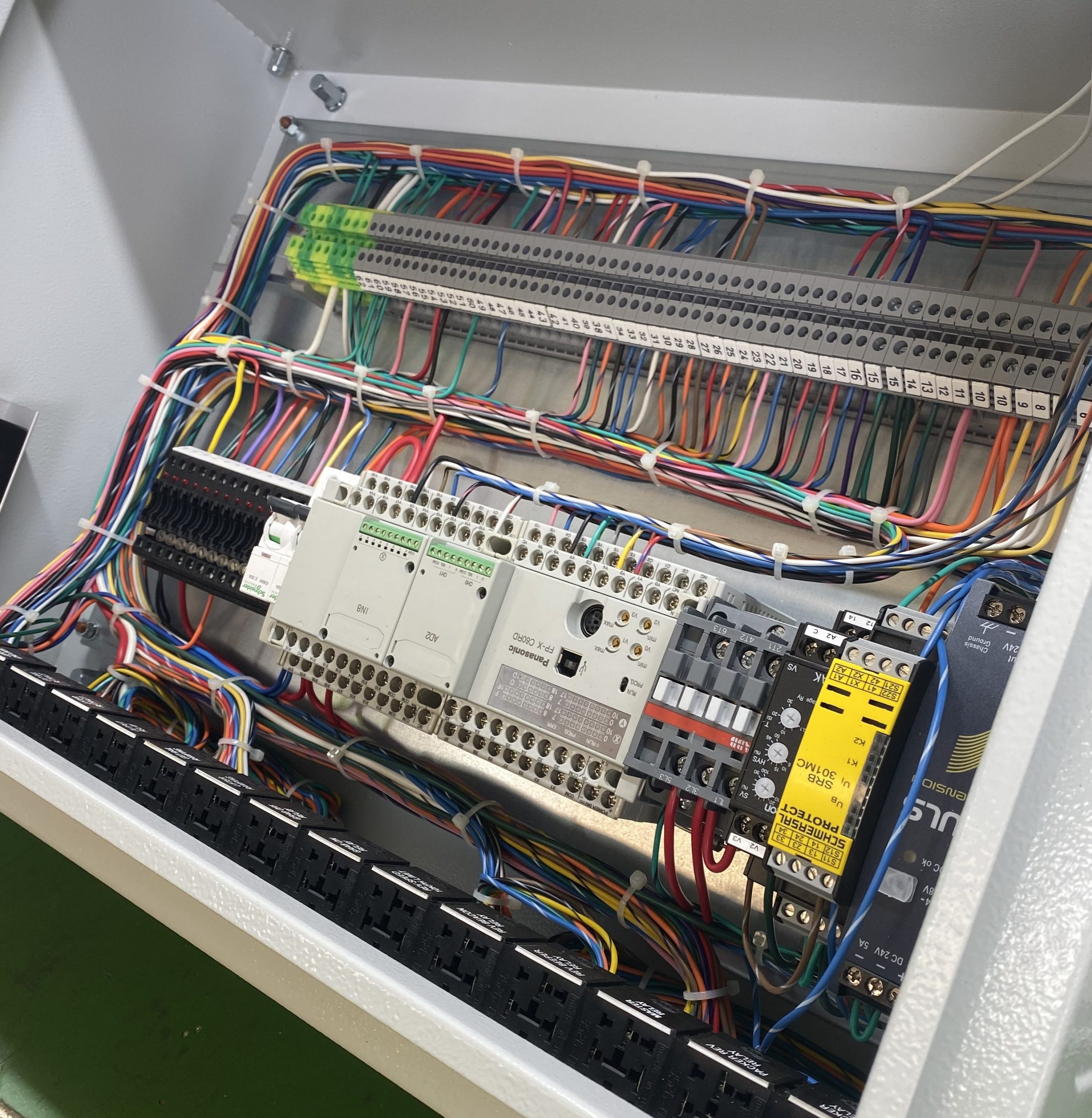

Building our own waste trucks enables us to tailor a customised waste solution for each of our municipal customers. The vehicles are built in our Chinderah based manufacturing plant, starting with a bare-bones truck cab chassis.

The body of the vehicle is designed by our engineers from the ground up, fitting specialised waste industry equipment. Each vehicle is also fitted with our tried and trusted In-Vehicle Waste Management systems.

The management system has evolved over many years and is well tuned to the current demands of the waste industry. All statistical data is transferred from the collection vehicle to the cloud in near real-time. This enables us to more efficiently identify and flag waste collection incidents such as recycling contamination. At the same time the cloud based management portal enables council officers to view reports, operational data, and resident customer service information.

Various holding tanks

Septic tanks

Sullage tanks

Grease trap waste

Triple interceptor pits

Treatment plant pump outs

Cleaning/servicing of tanks

Portable toilet pump outs

At Solo Resource Recovery we understand the importance that statistics play in the overall management of municipal waste. That’s why all of our vehicles are fitted with state of the art In vehicle management systems (IVMS). The IVMS is primarily responsible for capturing driver input such as contamination events, lifter arm events, and bin presentation issues. GPS tracking monitors the waste collections in real-time, while continuously tracking the position and status of all waste trucks. The IVMS is also responsible for capturing and storing a continuous 360 degree camera feed for long term archive.

Waste assets have never been easier to manage, with all collections monitored via GPS or RFID technology, allowing our drivers to log service exceptions against customer assets. This allows for detailed operational reporting with data from the coal face. The integration between the IVMS and the customer service module simplifies management of customer service tickets, council memos and changes to bin assets.

The demands on the waste industry to improve recycling and divert waste from landfill has resulted in a number of improvements to our waste management technology, from the vehicle cab through to the office. In particular the capture of digital images depicting bins with contaminated recycling waste which are automatically stored against the correct property address and retrievable on demand. The cameras are leading edge and play an important role in safety and efficiency across our fleet.

All of the Solo collections vehicles are designed & built by our own manufacturing and engineering department. All of our trucks comply with a rigorous monthly maintenance regime, which is tracked via our fleet and business management systems. We take pride in our trucks with our vehicles being clean, well presented, safe, and compliant with all EPA requirements. With over 700 vehicles operating across Australia, Solo offer an extensive range of contingency and value added service options.

Solo utilise cutting edge Vehicle Management Systems, which include reliable and informative GPS tracking systems, contaminated waste tracking, and photo’s for compliance or reporting purposes. Data is collected, validated, and managed to Council requirements by Solo’s own internal experienced database managers, and IT department.